- Pharma metal detector for small, high-flow loose pharmaceutical products, like tablets and capsules.

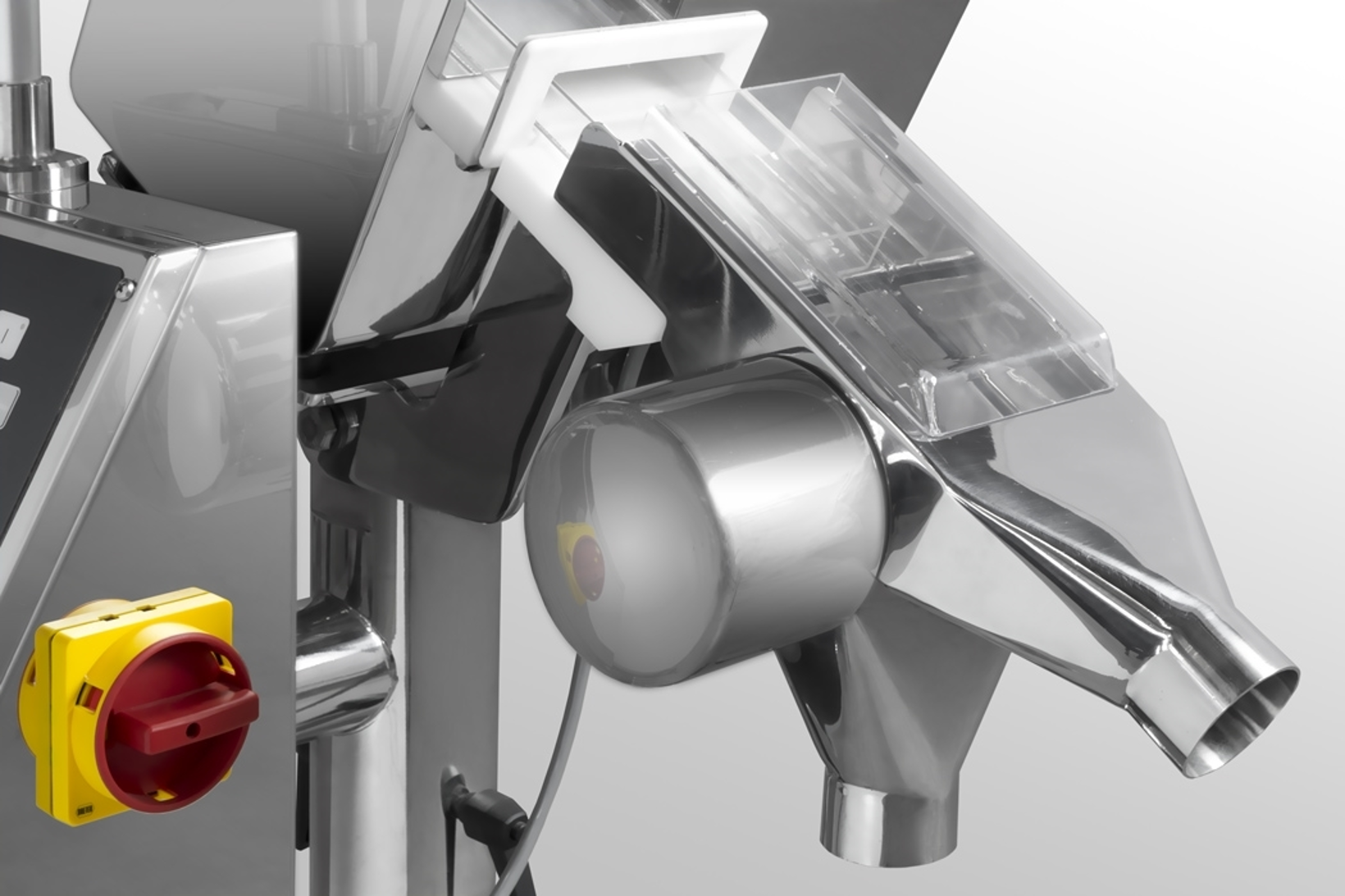

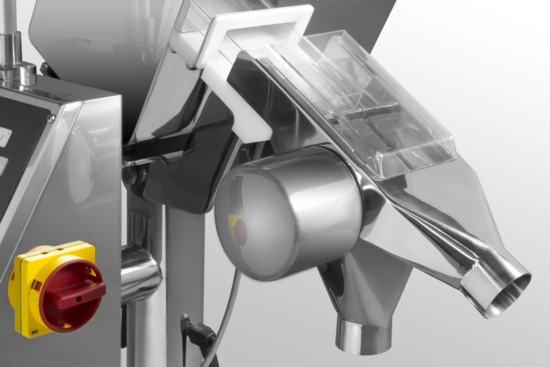

- Metal detector MDF11 was specifically designed to meet the specific inspection requirements of the pharmaceutical sector. A tilted chute in an inert material, easily removable and suitable for direct contact with the product, goes through the metal detector coil. Should metal contaminants be detected while the product is transiting, a flap is activated, which diverts the contaminant out of the production flow.

- Equipped with regulators that make it highly adaptable, this pharmaceutical metal detector is able to scan 10000 pieces/minute and can detect any type of metal contaminant: ferrous, non-ferrous, and stainless.

- The multi-frequency electronics combined with advanced functions – like self-check, automatic calibration, and tracking – guarantee top-level performance and fully meet the standards in force for Pharmaceutical Metal Detection Systems and the need to minimize false rejects.

- Multi-frequency technology

The multi-frequency electronics result in high-level immunity from environmental interferences (dry, humid, cool and frozen) and extremely high sensitivity to all magnetic and non-magnetic metals, including stainless metals, thereby guaranteeing top-level performances. - Simple, functional electronics

Digital electronics with alphanumeric display complete with self-check, automatic balancing, and tracking functions. Bi-dimensional image digital principle of operation. Possibility of adjusting phases and storing up to 100 programs. An RS232 C serial port is also available. Multi-level password-protected access reduces human error to a minimum. - Stable, safe and easily serviced mechanics

The machine consists of a tilted chute that goes through the metal detector coil. Upon detecting metal contaminants, a flap is activated, which diverts the contaminant out of the production flow. The transit aperture is made with inert materials that ensure the coil is completely sealed. It is easily removable and can be sanitized completely. It is available with two different transit dimensions: 95x22mm and 95x32mm. The control panel, with IP54, is on-board and the entire main support structure is made of stainless steel with a ballasted base to increase insensitivity to external vibrations and guarantee high-level mechanical stability to the unit. The structure allows you to adjust product infeed height (from 850 to 1000 mm), tilt angle (from 0° to 45°), and unit movement via locking wheels. The machine is available with or without a rejection bin.

MDF11 pharma

| Pneumatic supply | 0,6 Mpa |

|---|---|

| Power supply | 230 V 50/60Hz single-phase |

| Power consumption | 200 W |

| Tilt angle | adjustable |

| Climatic environment | from 5°C up to +40°C non-condensing (closed) |

| Regulations | Conformity with CE regulations and with international standards for Electrical Safety and Electromagnetic Compatibility |

Be the first to review “MDF11 pharma” Cancel reply

Reviews

There are no reviews yet.